Understanding the Capability of Membrane Layer Changes for Individual Interface Devices

The capability of membrane layer changes stands for a significant improvement in customer interface layout, incorporating performance with visual flexibility. As sectors progressively prioritize customer experience, recognizing the subtleties of membrane switch technology comes to be important.

What Are Membrane Buttons?

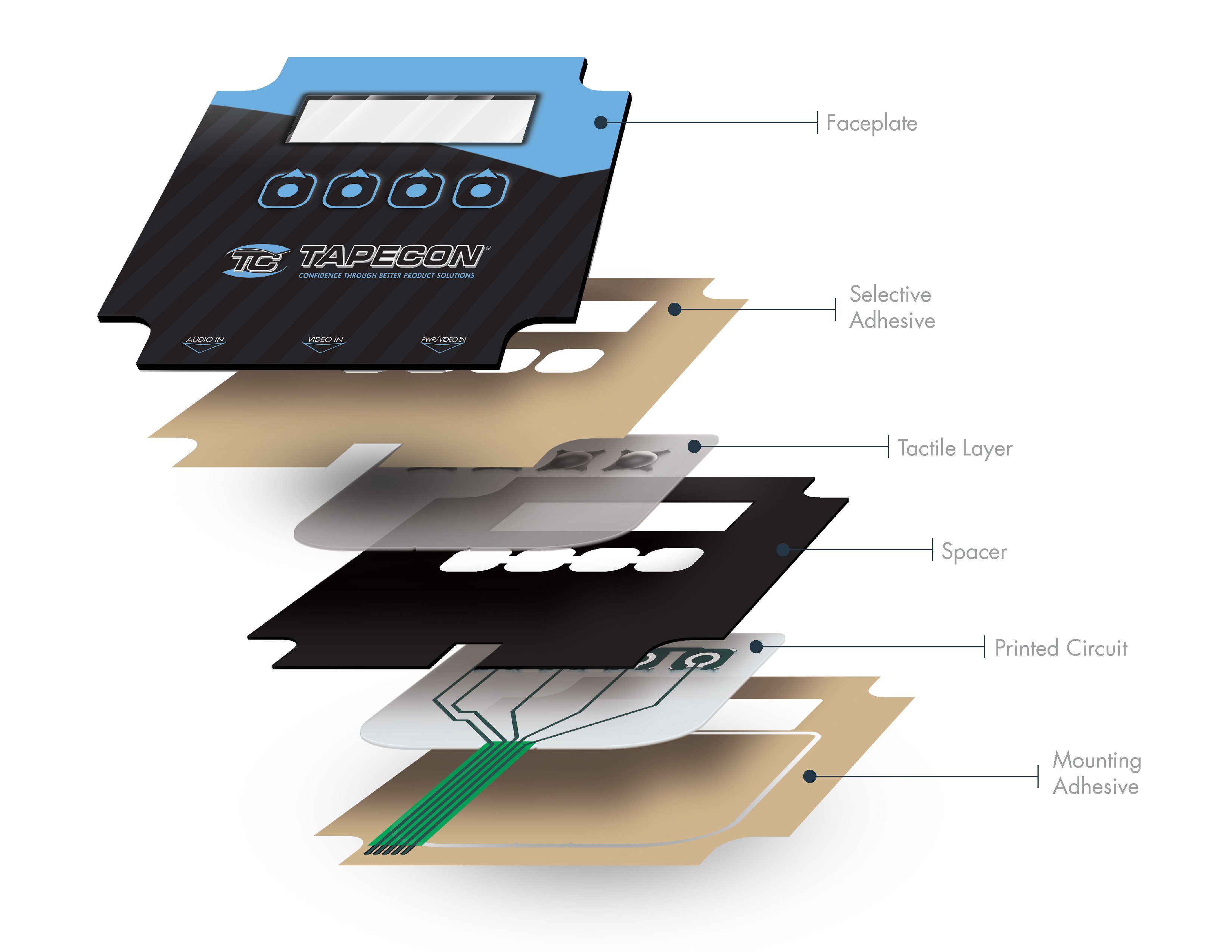

Membrane layer buttons are ingenious user interface gadgets that assist in customer interaction with digital equipment. These functional parts include several layers, including a graphic overlay, spacer, and a published circuit layer. The style enables a seamless integration into numerous digital tools, boosting both the aesthetic and practical aspects of customer interfaces.

Membrane layer buttons are commonly employed in a wide variety of applications, from family home appliances to industrial machinery and clinical gadgets. Their building generally features a thin account, making them an ideal selection for small designs. The responsive feedback given by these buttons can be crafted to satisfy specific user choices, ensuring effective interaction in between the individual and the gadget.

Toughness is another significant benefit of membrane buttons, as they are resistant to dust, dampness, and chemicals, which enhances their life-span sought after environments. In addition, these switches can be personalized in regards to form, dimension, and graphic design, enabling branding and user-specific attributes. In general, membrane switches represent a practical service for improving customer experience in digital devices, combining performance with aesthetic charm in a reliable manner.

How Membrane Switches Over Job

Operating on a simple concept, membrane layer changes utilize a layered building and construction to sign up customer input effectively. Each button consists of multiple layers, consisting of a printed circuit layer, a spacer layer, and a leading visuals layer, which are made to interact perfectly. When a customer presses the top layer, it presses the spacer layer, bringing the conductive components of the circuit layer right into call with each various other.

This get in touch with creates a closed circuit, signaling the gadget to carry out a certain function. The design permits for different arrangements, consisting of tactile feedback, which can boost the individual experience by providing a physical experience upon activation. The products made use of in membrane switches usually include flexible substratums, such as polyester or polycarbonate, which guarantee sturdiness and durability versus wear and tear.

Secret Advantages of Membrane Switches

Another substantial advantage is their density. Membrane layer buttons are slim and light-weight, which allows makers to conserve space in their tools without compromising performance. This function is specifically advantageous in applications where weight and quantity are important considerations.

Additionally, membrane layer buttons are resistant to dust, moisture, and chemicals, boosting their sturdiness. This resilience expands their life expectancy and minimizes the requirement for regular substitutes, leading to expense financial savings gradually.

Moreover, the tactile feedback provided by membrane layer buttons can be enhanced to boost user communication. They can include attributes such as increased switches or article distinct clicks, boosting usability and individual experience.

Applications Throughout Industries

Interface gadgets using membrane buttons prevail in a large range of sectors, showcasing their flexibility and capability. Membrane Switch. In the clinical sector, membrane buttons are integral to tools such as diagnostic devices and client surveillance systems, where their sturdiness and convenience of cleaning are essential for preserving hygiene criteria. In the automobile sector, these buttons are utilized in dashboard controls and infomercial systems, offering a streamlined and contemporary interface for users.

Additionally, the customer electronic devices sector take advantage of membrane layer switches in appliances and handheld gadgets, where portable design and easy to use user interfaces enhance user experience. Industrial applications additionally utilize membrane switches for control board in equipment and automation systems, emphasizing their toughness and resistance to harsh settings.

In the aerospace and protection industries, membrane layer switches are made use of in cabin controls and tools, where reliability and efficiency under extreme conditions are paramount. In addition, the pc gaming industry progressively incorporates membrane layer switches in controllers and game makers, adding to an interesting individual experience. In general, the versatility of membrane layer switches over allows their prevalent use across many markets, underscoring their significance in modern-day interface style.

Future Fads in Membrane Layer Switch Technology

Additionally, making use of advanced products, such as polycarbonate and polyester films, is expected to increase, providing improved resilience and resistance to ecological stress factors. These materials add to the total longevity of membrane layer buttons, making visit here them suitable for harsher commercial applications.

Moreover, the consolidation of clever innovation, including IoT connectivity, will certainly allow membrane layer buttons to communicate with other gadgets and systems, promoting a more interactive individual experience. This pattern straightens with the expanding demand for smart tools throughout various sectors, from health care to customer electronic devices.

Lastly, modification choices are expected to expand, allowing makers to produce bespoke solutions tailored to particular customer needs and preferences. These growths will certainly position membrane buttons as important parts in the development of interface modern technology.

Verdict

To conclude, membrane layer changes represent a pivotal innovation in customer interface innovation, offering a reliable and functional remedy for varied electronic applications. Their layered building helps with small style, while functions such as responsive feedback improve individual interaction. The longevity versus environmental variables further solidifies their utility across numerous sectors. As advancements in product science and touch picking up technologies continue, the functionality and applicability of membrane layer buttons are anticipated to broaden, enhancing their relevance in modern electronic tools.